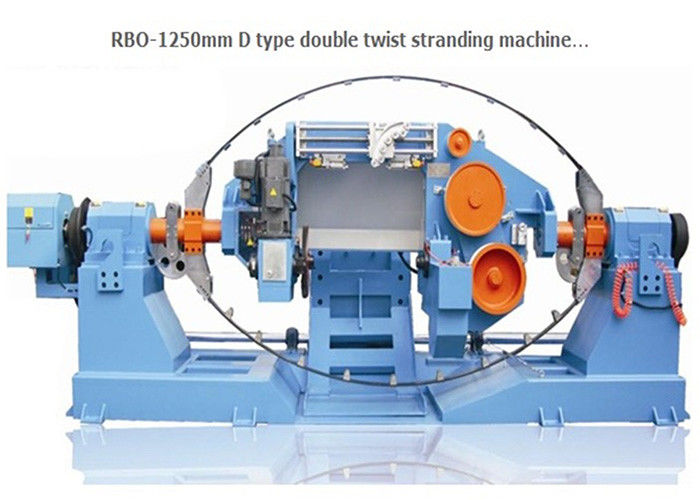

1250 Wire Bunching Machine stranding copper wire PVC wire Al wire and below 7 wires conductor

- Introduction

This equipment is dedicated to twist aluminum and copper round compress conductor.

This project contains a external rotation pressure die structure, and provide the required traction used for compress conductor, when the conductor compress, the take-up partof bundling machinewill obtain, and have a special line way to reduce torque between rotating traction wheel and take-up bobbin, can be ensure that there is a good round conductor.

- Purpose & characteristic:

This machine is suitable forstrandingcopper wire ,PVC wire, Al wire and below 7 stands conductor, mainly used for sectional area for copper 50mm2,AL 70mm2.

The production efficient is 4.5 times compared withtubular machine. This machine has appied a Chinese national patent, Patent No.: ZL 2010 2 0522064.5

| No. |

Name and specification |

Brand |

Qty. |

Unit |

Function |

Remark |

| 1 |

Wire inlet device |

|

1 |

Set |

Wire collection |

|

| 2 |

Tension balance(7 pcs) |

|

1 |

Pc |

Balance tension |

|

| 3 |

1250mm double twist stranding machine |

|

1 |

Set |

Wire stranding |

|

| 4 |

Rotation die stand |

|

1 |

Set |

Conductor

compact

|

Compacted die |

| 5 |

Meter counter |

|

1 |

Set |

Metering |

|

| 6 |

PLC type main electric cabinet |

|

1 |

Set |

System control |

|

| 7 |

Die or roller |

|

1 |

Set |

Conductor finish size |

For one size |

| 8 |

Color marking :A. Germany Blue B. Computer color C. New blue-grey D. or provided sample color by the client |

| 9 |

Direction of production line: Left pay-off Right take-up

Right pay-off Left take-up

|

| 10 |

Installation length of the production line see installation schematic diagram |

A. Main specification:

1.Wire diameter of wire inlet: Φ1.0mm-3.0mm/7cores(copper wire ),

PVC wire diameter of wire inlet:Φ2.0mm-Φ6.5mm/2-4cores

2. Conductor section area of stranding: 3.5-50mm2

3. Lay range(copper and aluminum): 40-350mm. Thumbwheel type setting automatic calculation and adjustment.

4.Wire diameter of stranding:

1) Copper wire, Φ3.0mm-10mm

2) PVC wire diameterΦ5.0mm-15mm.

3) Stranding section (flexible strands):3.5-70mm2

4) Stranding section (1 + 6):3.5-50mm2

5) Compacted copper:3.5-50mm2

6) Compacted aluminum:3.5-70mm2

7) Maximum line speed:150m/min

5. Direction of twisting: S.Z. (Left and right twisting direction can be selected).

6. Speed of rotation body: 800 RPM/MAX. (1600 Twist).

7. Power:

Main frame: 55KW DC Motor + Digital control

Capstan: 30KW DC Motor + digital control

Spooler tension: 7.5KW DC Motor + digital control

Traverse unit: 1.5KW induction motor + Siemens inverter

Rotation die stand: 1.5KW induction motor + Siemens inverter

8. Spooler drum size: Max 1250mm

Spooler load capacity: Max 3500KG

9. Power source: 380V, 50Hz(or depend customer’s requirement)

10. Drum loading and unloading :

Type: Air pressure shaftless type.

Bobbin load /unload:bobbin load/unload by electric hydraulic lifting platform control

11. Low noise design: Main machine noise is insulated by safety cover, noise below -80db.

12. Brake: Disk brake.

13. Control: PLC system control.

1)D.C. motor digital control.

2)Wire-broken stop indicate,and own air pressure clamping device.It avoid to break wire during producting wire or threading wire on machines.

3)Meter reached will be stop.

4)Safety limit control.

5)Lighting control inside machine.

14. Used air pressure: 6Kg/cm2.

15. Add a side door at back of safety cover to convenient maintenance.

16. Add pressure wheel at the meter counting wheel.

17. Carbon brush connection to use the cable.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!